Sukmaji Indro Cahyono1, Eko Surojo, Teguh Triyono, Nurul Muhayat dan Triyono

Department of Mechanical Engineering, Faculty of Engineering, Sebelas Maret University

Abstract

Most of the welding workshops in the Jaten Karanganyar area work on small to medium construction works. The design drawing that the consumer wants is only made a manual sketch drawing as it is without following the ISO standard technical drawing rules and without going through the design process, so that the cost estimation and material requirements are only estimates. In addition, in the product manufacturing process, there are many measurement errors so that cutting and using materials are not efficient. Assistance in introducing and training on the use of CAD software in designing and designing products that are done with the welding process is the main focus of this PKM. The main targets of this service program are welders and local residents, especially residents of vocational school / vocational school graduates, to collaborate by raising a case study of designing and designing the making of the Fatimah Ar-Royyan Jaten Jaten mosque Gazebo. The result of this service activity is the growing interest of residents who want to learn and master the operation of CAD design software. Overall evaluation, there was an increase in the interaction between manufacturing partners (welders and consumer partners) with a visual presentation of 3D images and technical drawings, and better efficiency in the use of materials and processes.

Keywords: Design, Design, Welding Manufacturing, Engineering Drawing.

A. INTRODUCTION

The results of observations and situation analysis of the objective conditions of the UKM Welding Workshop in Jaten Village Karanganyar to date, the market segment in the welding workshop business in the Jaten area is classified as the same, namely the products used in the housing sector, such as fences, door trellis, stairs and others, There are few product variants, so the welding shop is sometimes flooded with orders but at other times it is quiet. Business competition is very tight because the number of welding workshops is very large while the number of customers is limited. See Figure 1.The process of mentoring entrepreneurs / SMEs in the PKM program is carried out by (D. Santoso 2017)

Figure 1. Condition and situation of the Sumber Rejeki Las Workshop in Sawahan Hamlet, Jaten Village

The main problem experienced by the welding workshop partners, most of them are working on construction without using work drawings / technical drawings. The images that consumers want are only made manual sketches of the drawings without following the standard rules of technical drawing. In addition, the expertise of the welder can do welding work by self-learning so that it has several weaknesses, including:

– Knowledge of designing designs that only follow pictures and examples that are already on the market / used by the community.

– Do not have technical drawing skills or operation of a qualified CAD drawing software that explains material requirements and design forms in detail.

– Welders’ knowledge of welding manufacturing design is lacking.

– Efficient material use and low measurement accuracy.

So from the description above it can be defined, the problem of PKM partners, namely the Sumber Rejeki welding shop, Dusun Sawahan, Jaten, Karanganyar. Therefore, the solutions carried out by the PKM UNS team are as follows:

First, provide an example of a standard process flow using ISO standard engineering drawings. Creating work drawing flow from design to welding process. In making a pilot product, a Gazebo design has 3 sizes. The engineering drawing has process details and sizes down to material requirements. The design development process in a community service program requires technical drawings (AF Zakki, 2019)

Second, provide training in the introduction of technical drawing using CAD software. Provide training on the use of technical drawings in design applications for welding. The process starts with a sketch or sample image that the consumer wants, then draws it using 3D software, details the parts / components with assembling modules, then continues to create ISO standard 2D engineering drawings along with the suggested assembling animation method. Training on the use of software in the PKM program was carried out by (E.A. Purnomo 2018) while the software for educational purposes was carried out by (F. Fitriani 2019) and (A. Yunita 2020).

Third, provide an explanation and understanding of welding engineering work drawings. Provide interactive input and explanation on how to design changes to adjustments to consumer wants and simplification as well as reading of image positions and additional information regarding the Gazebo manufacturing process.

he realization of a technology product that becomes a model for the flow of designs to manufacturing, Gazebo sizes 3 x 5, 3 x 3 and 2.5 x 2.5 meters which are used for mosque activities and society in general. A similar process is also applied in the engine design carried out by (J.Y. Prihatin 2019).

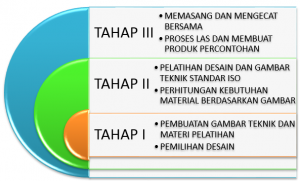

The description of the PKM UNS Service Activities Process is described in the following three stages:

Phase I is the making of gazebo design example materials that have been converted into ISO standard technical drawings. The process is packaged in steps which are then used as training material in stage 2. The process of sketching and selecting the design is an agreement between takmir and mosque congregation that is adjusted to the condition of the land where the gazebo will be built.

Phase II is training and introduction to technical drawings that help in the welding process in making a gazebo. There was a change in the plan at this stage where the initial plan of this stage was training using CAD software. However, due to the conditions of computer facilities and different backgrounds of expertise, training was not possible only once so that at this stage an introduction to the use of CAD software was held which was expected to grow interest among residents and when computer facilities were available, training activities were carried out that brought in tutors from Engineering. UNS machine.

Stage III is a welding training practice by making three kinds of gazebos in front of the Fatimah Ar-Royyan Jongkang mosque with matching funds from the third partner, Takmir Masjid Fatimah Ar-Royyan. The gazebo has a size; large 5×3 cashew gazebo, 3×3 meter medium gazebo and 2.5 x2.5 cashew small gazebo, which have been designed by the UNS PKM Team involving certified welders to further strengthen understanding of technical drawings. The summary of the implementation stages can be seen in Figure 2.

Figure 2.Stages in the implementation of community service.

B. IMPLEMENTATION AND METHODS

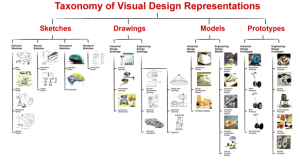

The making of this training material was carried out by the PKM UNS team on the Mechanical Engineering campus which packaged the design and design flow training material so that it was easily understood by the community. Based on engineering drawing theory, visual design representation in Figure 3, in designing to finished products requires at least 4 steps, including; the formation of sketch images, the formation of 3D / 2D images, the formation of selected models, and finally the prototyping.

Figure 3.Taxonomy of visual design representations (Pei.E 2011)

The design process of making a design with an example of a mosque gazebo case begins by looking for a design example, which is then made a sketch image. With the reverse engineering method, a new product is made by redrawing the old product after efficiency and improvement. This sketch image is a guide in making a 3D model for a new gazebo product. This sketch image is an agreement that has been agreed by the consumer, in this case, it is plural and takmir and is adjusted to the condition of the land area. See Figure 4.The planning of this Gazebo Image is like the planning of an easel frame in the construction of the Al-Ikhwah mosque (Wibawa, B.A 2016)

Figure 4. A sketch drawing as a reference for the design of 3 gazebo models using the reverse engineering method.

Figure 4 is a sketch of the reference that has no size, but it is an agreement that the design will be designed with the desired area. The image is then redrawn in 3D using Solidwork software which is then packaged into material to be studied together with the community.

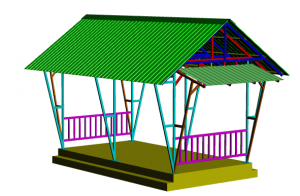

Figure 5. A sketch drawing as a reference for the design of 3 gazebo models using the reverse engineering method.

Figure 5 is a 3D drawing of the gazebo produced by the finished CAD software which is then consulted with the user and the maker, namely the welder. Several changes occurred regarding the process of joining the frame into modules to facilitate the transfer from the welding shop to the installation site.

Figure 6. 3D drawings are broken down by components by grouping the modules for easy transfer to the gazebo installation site.

In the process of splitting 3D images into module components as seen in Figure 6, an animated video of the installation stages is also made which is hoped that even the maker or installer without expertise can understand each step of the manufacture well. Making videos in delivering information is better than using written descriptions and pictures (A.A.R Awaludin 2019) and (Irawan.E 2019).

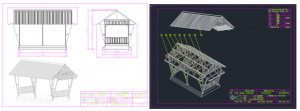

Figure 7. 3D images are converted to 2D images.

The next process is to convert all 3D images into 2D images, making it easier to detail the size and naming of components. See Figure 7 above.

Figure 8. All 3D component images are converted into 2D images and given detailed sizes following ISO standard rules.

Images that have been converted to 2D are sized according to ISO standard rules, so that in detail they can be understood and the requirements for the length of the frame are also made. The estimated cost required can be estimated properly. The calculation results and required costs are very expensive so that some frames are reduced and some frames are reduced in size to save on manufacturing costs. However, based on calculations and computer simulations, the gazebo construction remains above the allowable construction safety factor. See Figure 8.

Figure 9. All gazebo models are made with the same and continuous process flow.

In the final stage the changes made are adjusted and the calculation of BOM (bill of material) or what is commonly called a drawing to predict material requirements so that cost estimates can be saved and more accurate than just estimates. See Figure 9.

The initial training with 22 participants was not optimal due to the covid outbreak, but the participants’ interest was quite high, this can be seen from the many questions and the desire to master the operation of CAD software. The time required for training takes 8 meetings, due to the emergence of the Covid outbreak, further training is planned to be carried out online / online. See Figure 10.

Figure 10. (a) Training on the introduction of technical drawings and CAD software in making gazebos. (b) The manufacturing process by a welder

C. RESULTS AND DISCUSSION

The results of community service activities, namely the third partner of the Fatima Ar-Royan Mosque being the recipient of the product of the welder’s training activity in the form of a Gazebo. While the second partner, namely welders and residents of vocational school / vocational school graduates who study, gain knowledge and experience in designing and making ISO standard technical drawings that are taught even though the Covid outbreak has had a significant impact on community service activities. See Figure 11.

Figure 11. Installation of design products using a CAD program in the form of a Gazebo at the Fatima Ar-Royan Mosque.

Design evaluation that is expected in accordance with consumer desires. Only a few parts need to be reduced due to overdesigning (the material chosen is too large). Estimated calculation of the Gazebo structure is able to withstand strong winds in the rice fields with speeds reaching 76 km / hour and from the initial estimation the structure is able to withstand the load of humans who are installing Galvalume roofs. In general, the structure is classified as safe.

The initial estimate of the welder estimated that the manufacturing process of the Gazebo weld without the aid of Engineering Drawings would take 6 weeks. After being given training and technical drawings, one Gazebo unit can be completed for 5 days.

Cost estimation using technical drawings does not change much between planning and implementation, but the efficiency of material use increases, this can be seen from the very little remaining unused material.

D. CLOSING

Conclusion

In engineering design science, partners engaged in welding require expertise in planning. So far, the planning and design process has only depended on instinct and trial and error. Planning also depends on the order and the safety factor and material requirements have not been calculated. Sometimes it is based on experience in other places or designs that are made so safe that a lot of material is wasted becoming thicker or heavier. The use of CAD software is very helpful in the design process and accurate cost estimation.

The progress during the activity was quite good, it was necessary to increase intensive training in drawing with the help of CAD software and understanding of making measurements according to ISO standards.

Suggestion

Participants’ expertise in mastering the design material requires a minimum of experience in the engineering field such as Vocational Schools or SMKs. In addition, supporting facilities such as a computer are very much needed, and legal licenses for CAD software such as Autocad and Solidwork which are owned by the University need to be opened for the benefit of community service like this and research.

Thank-you note

This service activity has been funded by the P2M LPPM UNS program under the auspices of the Ministry of Research, Technology and Higher Education of the Republic of Indonesia.

E. REFERENCES

Santoso, D., Indarto, I. and Santoso, A., 2017. Pemberdayaan Usaha Kecil Mikro (UKM) Menuju Kemandirian Melalui Pembinaan Kewirausahaan, Permodalan, dan Pemasaran di Kecamatan Tugu. E-Dimas: Jurnal Pengabdian kepada Masyarakat, 8(2), pp.166-173.

Zakki, A.F. and Suprapti, A., 2019. Pengembangan Desain Bak Celup untuk Proses Pencelupan, Lorotan, dan Pewarnaan pada Produksi Batik Semarangan. E-Dimas: Jurnal Pengabdian kepada Masyarakat, 10(2), pp.194-199.

Wibawa, B.A. and Saraswati, R.S., 2016. Perencanaan Pembangunan Masjid Al-Ikhwan Kelurahan Karangayu, Semarang. E-Dimas: Jurnal Pengabdian kepada Masyarakat, 7(1), pp.1-14.

Fitriani, F., Maifa, T.S. and Bete, H., 2019. Pemanfaatan Software Geogebra Dalam Pembelajaran Matematika. Jurnal Pendidikan dan Pengabdian Masyarakat, 2(4)

Purnomo, E.A., Handayani, S., Kadarwati, S., Pohan, S. and Sumarno, S., 2018. IbM Pemanfaatan Software Camtasia untuk Meningkatkan Pendidikan Karakter Guru TK PGRI 10 Siliwangi. E-Dimas: Jurnal Pengabdian kepada Masyarakat, 9(2), pp.141-148.

Yunita, A. and Jufri, L.H., 2020. Pelatihan Guru Matematika Dalam Penggunaan Software Geogebra. Jurnal Pengabdian dan Peningkatan Mutu Masyarakat (Janayu), 1(2).

Prihatin, J.Y., Pambudi, S., Kustanto, H., Prayoga, S. and Purnosiwi, Y.T., 2019. Rancang Bangun Mesin Pengering Double Blow Chamber di UKM Karak Sukoharjo. E-Dimas: Jurnal Pengabdian kepada Masyarakat, 10(2), pp.262-265.

Pei, E., Campbell, I. and Evans, M., 2011. A taxonomic classification of visual design representations used by industrial designers and engineering designers. The Design Journal, 14(1), pp.64-91.

Awaludin, A.A.R., Hartuti, P.M. and Rahadyan, A., 2019. Aplikasi Cabri 3D Berbantu Camtasia Studio untuk Pembelajaran Matematika di SMP. E-Dimas: Jurnal Pengabdian kepada Masyarakat, 10(1), pp.68-75.

Irawan, E., 2019. Digitalisasi Madrasah di Era Revolusi Industri 4.0: Refleksi Kegiatan Pengabdian Kepada Masyarakat di Kabupaten Ponorogo. E-Dimas: Jurnal Pengabdian kepada Masyarakat, 10(2), pp.160-168.